Service

Our Core Service

24/7 Online

Message or email us if you need any help

OEM & ODM

Flexible customizations for your selection

Free Samples

First-time buyer? Free samples for quality test

High Durability

Remain scratches-free and intact for at least 1 year

Manufacturing Process

Design & Prototype for Your Requirements

After accessing your creative ideas and requirements about your brand and new product line, using CAD, we create digital designs to visualize, modify, and optimize our construction process. With this, the production of jewelry with complex geometries is made simpler.

Following this, a suiting mold that can replicate the design is made. Stainless steel raw material is poured into the mold to solidify and produce the jewelry. This process allows the continuous production of pieces of jewelry at a fast rate.

Following this, a suiting mold that can replicate the design is made. Stainless steel raw material is poured into the mold to solidify and produce the jewelry. This process allows the continuous production of pieces of jewelry at a fast rate.

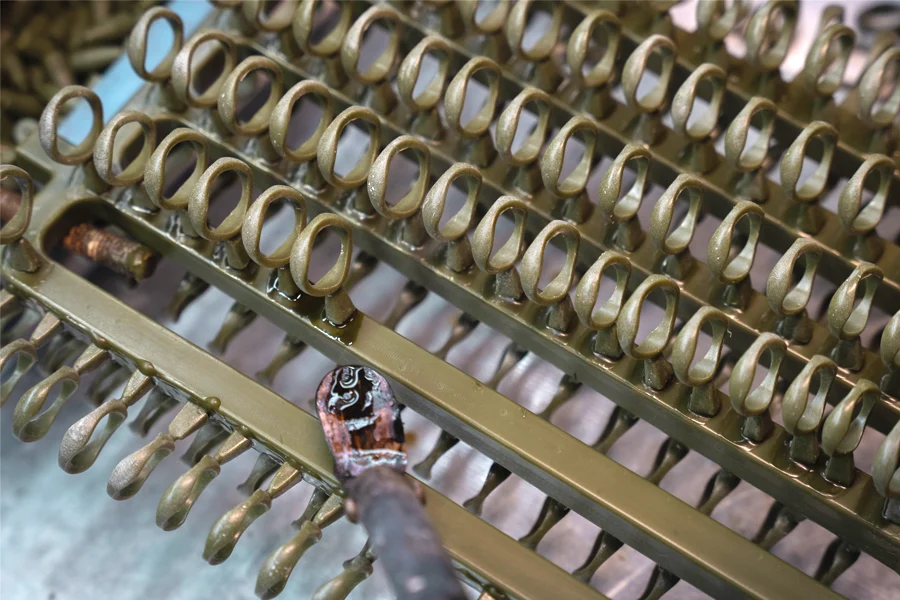

Lost Wax Casting & Molding Bring Your Idea to Life

This is a metal casting process in which molten metal is poured into a predetermined mold. The mold is previously made using a wax model that has since been melted and drained out.

With our years of experience and unmatched expertise, we manufacture beautiful pieces of jewelry using this procedure. It’s most suitable for smaller, complex parts, as it offers an excellent degree of precision and flexibility. It also supports the attachment of numbers, letters, logos, and many more.

With our years of experience and unmatched expertise, we manufacture beautiful pieces of jewelry using this procedure. It’s most suitable for smaller, complex parts, as it offers an excellent degree of precision and flexibility. It also supports the attachment of numbers, letters, logos, and many more.

Stone Setting for Further Decoration

This involves the fixing of gemstones in metal casings. With our extensive capabilities in manufacturing attractive jewelry, we attach several types of stone designs, including zirconia, pearl, Czech stone, bead, etc.

The essential objective of this process is to hold the gemstones securely and boost their beauty by sharing the cut, color, and clarity.

The essential objective of this process is to hold the gemstones securely and boost their beauty by sharing the cut, color, and clarity.

Hand Polishing Increases Clarity & Attraction

Polishing has to do with smoothing rough surfaces to ensure a clean and attractive finish. For optimal results, a variety of machines and handheld tools are used to remove uneven and blurry surfaces.

At Jusnova, we start off by shaping and amending contours to get a uniform surface. Afterward, lighter polishing mediums are applied to reveal a brilliant shine. This magically unlocks the beauty of the jewelry.

At Jusnova, we start off by shaping and amending contours to get a uniform surface. Afterward, lighter polishing mediums are applied to reveal a brilliant shine. This magically unlocks the beauty of the jewelry.

Electroplating Enhances Quality & Beauty

Involves the covering of a piece of jewelry made from a certain metal with a layer of another metal. For example, 10k to 24k gold can be plated on the jewelry, which is done to enhance the aesthetic value, adding a layer of shine and protection.

We also apply this process to improve the durability of jewelry, making sure that they don’t tarnish quickly. Instead, they remain polished and attractive as when they were initially manufactured.

We also apply this process to improve the durability of jewelry, making sure that they don’t tarnish quickly. Instead, they remain polished and attractive as when they were initially manufactured.

Repetitive Inspection to Ensure Quality

Having established strict quality control measures, we carefully inspect the result of each manufacturing procedure to ensure that all the jewelry that comes out of our hands is qualified. Following the demands of clients and the industry standard, all our production procedures are made to be of optimal quality.